What is Pointing in Construction? Types of Pointing? Advantages and Disadvantages of Pointing

Table of Contents

Pointing in Construction

Pointing in construction is the skill of finishing wall mortar joints and similar structures in exposed stone masonry or brick masonry with either lime mortar or cement mortar to protect the joints.

In order to protect joints, from the effects of weather and to amplify the appearance of building structure pointing in construction works is done.

Introduction to Pointing

Pointing is done with following types of mortar mixes:

Cement mortar 1:3 mix(1 cement: 3 sand).

Lime mortar 1:2 mix(1 lime: 2 sand).

Usually, complete wall or a whole structure is pointed as a result of faulty and defective points as it cannot simply be found and detected and adjoining joints might also need to have repaired.

The mortar is closely packed in thin layers during Pointing in construction and placed on a concave,clean, and finished surface.

Scope of pointing:

- Pointing in construction keeps and maintains the joints of structures.

- It is economical, and most appropriate in low rainfall locations.

- The natural beauty of the material should be displayed.

- Pointing in construction provides resistance to bricks and stones used in construction against weather conditions.

Types of Pointing :-

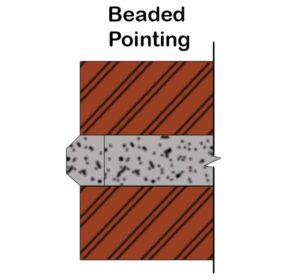

1.Beaded Pointing:

Beaded pointing provides very good appearance but it is very difficult to maintain.

The raked joints are filled with a mortar in this type of pointing in construction and finished flush with the face of the structure after which beded by a steel highway with a concave edge placed in between the joints.

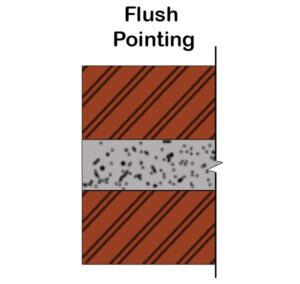

2.Flush pointing:

In any pointing, joints are completely flushed and raked with the face of the brick masonry.

The sides are rightly trimmed. Flash pointing is the easiest method and is widely used in masonry work.

It does not provide good look however it is very sturdy and it doesn’t allow dust, dirt to lodge over it.

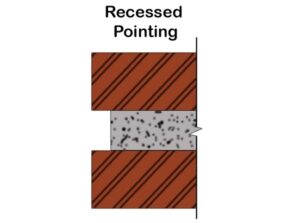

3.Recessed pointing:

Recessed pointings is one other type of pointing in construction in which the mortar is kept vertical but inside the surface of the wall with the help of proper machinery and equipment.

It is best suited to withstand the work of bricks and provide better texture and better quality mortar.

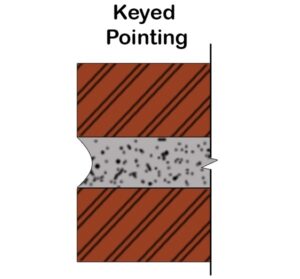

4.Rubbed or grooved pointings:

In this rubbed pointings, the raked joints are filled up, flush with the wall or face and semicircular notches are established by a special tool.

This type of pointing in construction is most commonly used to enhance the appearance of the wall.

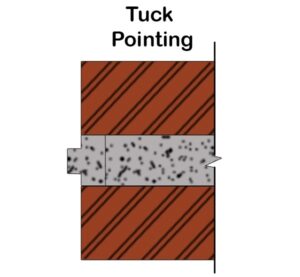

5.Tuck Pointing:

In this Tuck Pointing, the mortar is pressed inside the joints and finished flush with the wall face.

When the mortar is still wet, a rectangular groove is formed in the centre of the joints.

The groove is then covered (filled) with white lime putty and little amount of silver sand, projecting little outside the finished surface of the plaster indicating it.

It gives an eye catchy and beautiful appearance but the fillet part is not very durable.

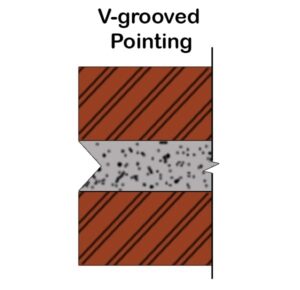

6.Vee pointing:

In Vee type of pointing in construction ,either ‘V’ shaped grooves are glutted in the finished surface of the plaster when it is still wet or by projecting the ‘V’ shape of the outside face of the surface of wall.

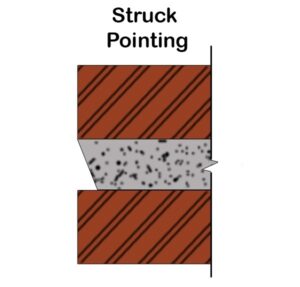

7.Weathered or struck pointings:

In this Weathered pointing, the face is kept inclined instead of vertical.

The upper edge is pushed inside the masonry by about 10 mm and the lower edge is finished level with the face of the masonry.

This type of pointing in construction is used for brickwork for finishing horizontal joints.

Method of Pointing :-

- All the mortar joints in the masonry are raked out to a depth of 15-20 mm with the help of the pointings equipment and tools

- Lose mortar and Dust are cleaned.

- The surface and joints and are washed with water and kept wet for some time.

- The mortar is taken and the old mortar is pressed into the joints, then filled with small trowels to make contact with the joints.

- Joints are discarded- sunk, flushed or raised depending on requirements, removing excess mortar.

- In the finished work curing is done for 3-4 days in cases of lime mortar and 10 days when cement mortar is used.

Advantages of Pointing in Construction :

- Pointing in construction improves the overall look of the structure.

- Pointing reduces the need for other repair or rehabilitation work.

- Pointing protects the walls of the structure from adverse weather.

- Pointing in construction improves the structural strength of the building.

Disadvantages of Pointing in Construction :

- In winter, the wet brickwork freezes and rotting.

- Spalling stones or bricks begin to appear.

- Pointing is sometimes responsible for the terrible damage to various walls.