What is Grillage Foundation ? Types of Grillage Foundation ? Steel vs Timber Grillage Foundation

Table of Contents

What is Grillage Foundation

A grillage foundation is a sort of isolated footing used to support massively laden steel stanchions, particularly in areas where the soil bearing capacity is low. The foundation depth is limited to 1000 mm to 1500 mm. By using layers or tiers of joists, the load of the column or stanchion is distributed or spread across a vast area, with each tier placed at right angles to the next.

Waht are the Types of Grillage Foundation

There are two types of grilling foundations:

- Steel type grillage foundation.

- Timber type grillage foundation.

What is Steel Grillage Foundation ?

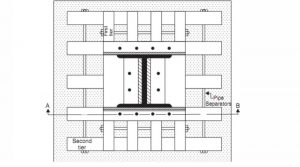

Steel grillage foundations are made up of two or more levels of strong steel beams known structurally as rolling steel joists (R.S.J.). The topmost tier of grillage beams is laid at right angles to the lowest tier in the case of twin tier grillage (which is often given).

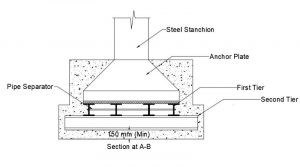

Each tire’s joists or beams are held in place by spacer bars with a diameter of 20 mm and pipe separators with a diameter of 25 mm. Below it, the grillage beams are encased in concrete. A minimum space of 80 mm is usually maintained between the grillage beams so that concrete may be poured readily and vibrated correctly to obtain the appropriate compaction.

However, the distance between the beams’ flanges should not exceed 300 mm or 112 times the flange width (whichever is smaller) in order for the filled-up concrete to act monolithically with the beams. It should be noted that the filled-up concrete does not carry any load; it simply serves to keep the beams in place and prevent corrosion.

On the outside sidewalls of the exterior beams, as well as the upper flanges of the top tier, a minimum concrete cover of 100 mm is maintained. A minimum of 150 mm of concrete should be poured beneath the lowest deck.

What is the Step by Step Method of Steel Grillage Construction

- The foundation is initially excavated to the requisite depth for steel grillage construction. In general, the foundation depth is shallow; nonetheless, it must be sufficient to support the two layers of grillage beams, as well as the gusset plates, angle cleats, and other components connecting the stanchion to the base (*a working space allowance must be made in the excavation).

- In any event, the depth should not be less than 900 mm. The foundation base should then be thoroughly leveled, and a rich concrete mix should be poured over the foundation dirt and compacted to a thickness of at least 150 mm. Concrete should be carefully compacted so that the layer becomes impervious to subsoil water, protecting steel joists.

- With the help of separators, the first layer of grillage beams of specified sizes is set over the concrete bed after it has been leveled and compacted. All of the beams’ upper surfaces are then leveled and laid in a single horizontal plane.

- After that, a thick cement or chemical grout is poured completely around the lower flanges of the beams to bind them to the concrete bed. The cement concrete is then poured between and around the first tier’s beams.

- The second tier of beams is then installed at an angle to the first tier and over the first tier’s top flanges. With the help of separators, they are correctly spaced. Then, between and around the steel beams, a second layer of concrete is poured.

- A base plate, anchor bolts, side angles, and gusset plate are used to attach the steel stanchion to the higher layer. These connecting pieces are likewise imbedded in the concrete, resulting in a uniform and rigid junction.

- On low-bearing-capacity soils, a steel grillage foundation is also required for a masonry wall. In such a case, the grillage foundation consists of a single tier, though two levels may be given in some cases where the wall is broader and supports heavy loads.

What is Timber Grillage Foundation?

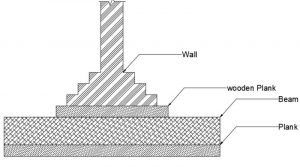

In the case of a severely laden wood column or a large load-bearing masonry wall, a timber grillage base is provided. Instead of steel joists, timber planks and beams are employed in this foundation.

This foundation is particularly beneficial in wet places where the soil’s bearing capacity is low and steel beams may rust due to undersoil water generated by any type of seepage.

Where no concrete is poured between the timber joists, the stress on the earth is limited to 50 to 60 kN/m. However, the lowest level concrete is provided in the case of steel grillage foundations, which are replaced by a timber platform composed of timber-planks.

What is the Step by Step Method of Timber grillage Construction ?

- The foundation is first excavated to the desired depth and leveled, after which the bottom layer of planks 50 to 75 mm thick and 200 to 300 mm broad is laid.

- The boards are stacked one on top of the other, with no gaps between them. A wooden beam tire, about 150 mm x 100 mm in size and spaced 300 to 500 mm apart, is set at right angles to the direction of the planks across this platform.

- A timber beam of the same section as the wood post is installed at right angles on top of this layer. The timber post is then attached to the timber beam at an angle.

- The foundation is made up of two layers of wood planks separated by rectangular timber sections (beams) that run perpendicular to the wall’s direction.

- The upper layer of boards, 75 to 100 mm thick when laid side by side, spanning the whole width of the wall foundation and running longitudinally along the wall.

- The lowermost section, or layer of boards, is 50 to 75 mm thick and runs longitudinally down the wall.

- The lower layer of timber planks, as well as the middle tier of timber beams, should, however, reach at least 450 to 600 mm on both sides of the wall footing base.

What are the Advantages & Disadvantages of Grillage Foundation

| Advantages of Grillage Foundation | Disadvantages of Grillage Foundation |

| Construction of the grillage foundation takes less time. | It is difficult to erect a column or stanchion and keep it aligned. |

| Grillage foundations are more resistant to seismic and vibrational forces. | The foundation’s beneath base must be correctly filled and compacted, and the dirt must be heated to make it hard. |

| This foundation outperforms all other foundations. | The piles beneath the foundation must be deeper. |

| Grillage foundations can distribute loads to a broader area, making them a safe choice. | The expense of excavation is higher in this foundation because it must cover a bigger area. |

| Grillage foundations save a lot of time and money by reducing the amount of concrete that needs to be poured. | The large items, such as beams and columns, must be safely hoisted using a crane, which is another costly concern. |

| The heat emitted by the home is reduced by this foundation. | A substantial uplift of the soil might cause this sort of foundation to form. |

What are the application of Grillage Foundation ?

The grillage foundation system is widely used in the following areas:

When bedrock isn’t available and a raft or mat foundation isn’t an option.

Unlike pile foundations, this foundation is lighter and less expensive, and it does not necessitate considerable excavation.

This form of foundation is less taxing on the environment.

The notable projects that make use of grillage foundation.

Project for an electrical transmission line.

The foundation for a telephone or television tower.

Steel stanchions or columns were used in any other tower-like building.

What are the Features Of Grillage Foundation ?

The following are the primary characteristics of grillage foundations:

- If you have a lot of steel and durable wood, it’s a good idea to use it as a foundation.

- It is advantageous to reuse rolled steel pieces after they have been removed.

- It is a wonderful alternative if the soil’s bearing capacity is limited because it is cheap cost and lighter.

- This foundation is the greatest option for pressure distribution across a big region.

Design procedure of Grillage Foundation

Grillage foundation design is a significant undertaking that requires the approval of a professional structural engineer. As a result, in this section, we’ll go over the standard processes in the design process.

- The computation of the loads and moments of the superstructure entering into the grillage foundation is the first step in the process of designing it.

- Engineers will be able to examine the base area necessary for the foundation using the aforesaid approach. Taking into account the soil’s current allowed bearing capacity.

- The number and size of the grid will then be determined by dividing the area.

- The layers of wood or rolled steel joists must slope upward from the edge to the top.

- The degree of slope taken into account will determine the size of the beam needed to withstand all of the moments and forces that will be applied to it.

- In order to keep the grillage beams in place and protect them from corrosion, concrete is poured between them.

- To allow for seamless concrete pouring, a minimum clearance of 800 mm must be provided around the grillage beams.

- To guard against atmospheric impacts and create a sturdy platform, the base concrete must be a minimum of 15 cm deep.