What is Flexible & Rigid Pavement? Pavement Design Failures Rutting In Pavement Texture?

Table of Contents

What is Flexible & Rigid Pavement? Pavement Design Failures Rutting In Pavement Texture?

In India, there are two types of pavements: rigid pavement and flexible pavement. In simple terms, a flexible pavement is a pavement layer made up of aggregates and bitumen that has been heated and mixed appropriately before being deposited and compacted on a granular layer bed. Rigid pavements, on the other hand, are formed of cement concrete or reinforced concrete slabs that are set over a low-strength concrete layer (Dry lean concrete, DLC) or a well-compacted aggregate layer, or both.

What is a Flexible Pavement ?

A bituminous surface course is laid over a base course and sub-base course in a standard flexible pavement. One or more layers of bituminous or Hot Mix Asphalt (HMA) may make up the surface course. Because these pavements have a low flexure strength, they deform when loads are applied to them. The joint action of the multiple layers of the pavement gives flexible pavements their structural capacity. The load from the vehicles is applied directly to the wearing course, then spread with depth in the base, subbase, and subgrade courses, and finally to the ground (in the form of a truncated cone).

The surface layer has the maximum stiffness (measured by resilient modulus) and contributes the most to pavement strength because the stress caused by traffic loads is highest at the top. The layers below are less firm, yet they are equally vital in the pavement’s structure. The weight is transferred from the top layers to the ground by the subgrade layer. Flexible pavements are built so that the load that reaches the subgrade does not exceed the subgrade soil’s bearing capability. As a result, the thicknesses of the layers above the subgrade vary depending on the soil strength, affecting the cost of constructing a pavement.

What is a Rigid Pavement ?

Rigid pavement gets their name from the fact that the concrete slab has a high flexural rigidity and hence the pavement structure deflects very little under load due to the high modulus of elasticity of the surface course. The concrete slab can distribute traffic loads across a vast area with a shallow depth, reducing the requirement for multiple layers to help alleviate stress.

Dowel bars and tie bars are present in the most prevalent types of rigid pavement. Dowel bars are short steel bars that link slabs mechanically without inhibiting horizontal joint movement. Tie bars, on the other hand, are deformed steel bars or connections that are used to keep the faces of abutting slabs together. They are not designed to operate as load transfer devices and are simply used to ‘bind’ the two concrete slabs together, despite the fact that they may provide some limited load transmission.

What is the difference between Flexible and Rigid Pavement

| Flexible Pavement | Rigid Pavement |

| At or near the surface of the pavement, it consists of a sequence of layers with the best quality materials. | It is made up of a single layer of Portland cement concrete slab with a high flexural strength. |

| The deformation of the subgrade and following layers on the surface is reflected in it. | It has the ability to bridge the gap between isolated failures and areas of insufficient support. |

| The aggregate interlock, particle friction, and cohesion all play a role in its stability. | Its structural strength is given by the beam action of the pavement slab. |

| The strength of the subgrade has a huge impact on pavement design. | Concrete’s flexural strength is an important consideration in design. |

| The load distribution through the component layers is the principle on which flexible pavement works. | Because of its stiffness and high modulus of elasticity, it distributes load over a large region of subgrade. |

| Variations in temperature caused by changes in atmospheric conditions do not cause stress in flexible pavements. | Rigid pavements are subjected to significant stresses as a result of temperature variations. |

| Since flexible pavements offer self-healing qualities, larger wheel loads can be recovered to some extent. | Excessive deformations caused by larger wheel loads are irreversible, resulting in permanent settlements. |

Types of failures in Flexible Pavement & Failures in Rigid Pavement

Failures of both flexible and rigid pavements are mentioned below:

Types of Flexible Pavement Failures:

A flexible pavement failure is defined as a localized depression and heaving up in the area. The pavement develops a wavy surface as a result of the sequence of depression and heaving up.

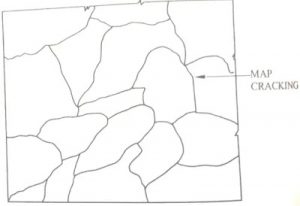

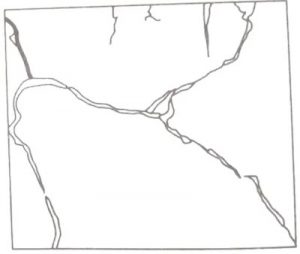

Map or Alligator Cracking:

The most prevalent type of failure, which is usually caused by fatigue. At first, map cracking only affects a small area of the road surface, but if not addressed quickly, it can spread to the entire road surface, resulting in potholes. Localized deterioration of the underlying base can also cause map cracking.

The following are the causes of map or alligator cracking in flexible pavement:

i) Asphalt hardening

ii) The surrounding area’s low temperature

iii) Inadequate drainage

iv) Plastic Deformation

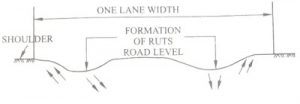

Rut Formation (Consolidation of Pavement Layers) Rutting in Pavement:

Rut formation or Rutting in pavement happens when loads are applied repeatedly to the same spot on the road. The major cause of rutting is the consolidation of one or more layers of pavement.

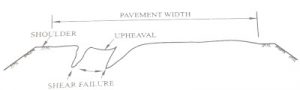

Shear Failure:

Shear failure happens when pavement compositions have intrinsic weaknesses. It causes the pavement material to shift, resulting in cracks.

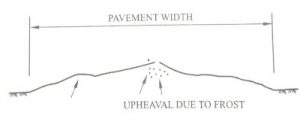

Frost Heaving:

Frost heaving refers to the localized upheaval of pavement caused by the ground water table and local meteorological circumstances.

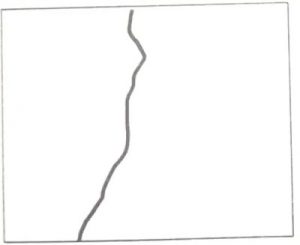

Longitudinal Cracking:

Longitudinal cracking in pavement occurs as a result of differential volume changes or other factors such as frost, embankment settlement, or side slope sliding.

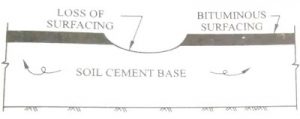

Pavement layer cohesion failure:

This failure arises as a result of insufficient bonding between the worn course and the underlying base course. As a result, material is lost, resulting in potholes. When bituminous surface is applied over a cement concrete foundation course, this type of failure is common.

Waves and corrugation formation:

This type of failure is caused by localized depression followed by heaving up in the area. On the pavement surface, this leads in the production of waves and corrugation.

Types of Rigid Pavement Failures:

Cement concrete scaling:

This failure arises as a result of chemical contaminants in the mix or inadequate mix design. Furthermore, if severe vibration is applied to cement concrete during construction, the mortar will come to the surface, which will be abraded during long-term use of the pavements, exposing the aggregate surface. This results in a rough and unattractive pavement surface.

Shrinkage cracks:

Shrinkage cracks in concrete constructions emerge during the curing process and can occur in both the longitudinal and transverse directions. These cracks may allow water to leak into the road, causing the concrete to disintegrate.

Development of warping cracks:

This failure happens when the joints are not effectively built to support slab warping at edges, resulting in the formation of cracks in the slab as a result of excessive loads. All structural flaws will be addressed if longitudinal and transverse reinforcement is applied at the joints.

Structural Cracks:

These cracks appear as a result of the slab’s insufficient thickness.

Joint spalling:

This failure happens when the filler material employed at joints becomes slanted, resulting in the production of an overhang layer on the concrete. As a result, the soil beneath the joint subsides, and severe cracking occurs near the joint.

Mud Pumping:

Mud pumping occurs when the cement concrete pavement moves downward and cracks under the impact of wheel loads. In most cases, it happens as a result of repeated loads vibrating the pavement, compacting the soil beneath the slab and leaving some gap beneath the slab. Water may seep into this region through joints and fissures, forming soil slurry.

What strategies are adopted for Flexible Pavement Design & Rigid Pavement Design

The design of either flexible of rigid pavement varies with soil conditions and the amount of traffic expected to be carried during its design life. In India, flexible pavements are planned using the California bearing ratio (CBR) of the subgrade soil and the anticipated number of cumulated axles (measured in million standard axles, msa) over the pavement’s design life. These pavements have a 15-year lifespan. The method of design allows for the use of both conventional and stabilized materials in any layer of the pavement, and the thickness of each layer is determined using templates provided by the Indian Roads Congress (IRC).

Rigid pavement thickness is influenced by traffic stress, subgrade soil, moisture, and temperature differential. Rigid pavements are designed for a period of 30-40 years. Initially, rigid pavements are thick enough to withstand fatigue failure. After that, the computed pavement thicknesses are tested for the crucial combination of load and temperature stresses.

Final thoughts on Flexible pavement and Rigid Pavement

Bituminous surfacing is used on the world’s major roadways. In the United States, for example, 86 percent of rural highways and 78 percent of urban roadways are of the flexible type. The majority of runways across the world have flexible pavements, and the Autobahn in Germany is no exception. The type of traffic and soil conditions, on the other hand, influence the pavement type.

Rigid pavement can be an excellent choice in regions where the soil subgrade is poor (such as clay) and drainage conditions are difficult to maintain at required levels of performance (such as in urban areas or circumstances where the road goes through habitation). Flexible pavements, on the other hand, might be more cost-effective when the soil subgrade is good and traffic isn’t too heavy.

The most significant benefit of flexible pavement is that it may be constructed in phases. According to an economic analysis conducted by an expert group for the upcoming Nagpur – Mumbai Access Controlled Expressway, flexible pavement will be substantially less expensive than rigid pavement if stage construction method is used.